Transfer hydrogenation of olive oil is a crucial process in the food industry, transforming olive oil’s properties and expanding its applications. This process involves the addition of hydrogen to the double bonds of olive oil’s fatty acids, resulting in significant changes in its chemical composition and physical characteristics.

Hydrogenation alters the fatty acid profile of olive oil, reducing its unsaturated fat content and increasing its saturated fat content. This modification affects the oil’s melting point, texture, and oxidative stability, making it more suitable for certain industrial applications.

Hydrogenation Process

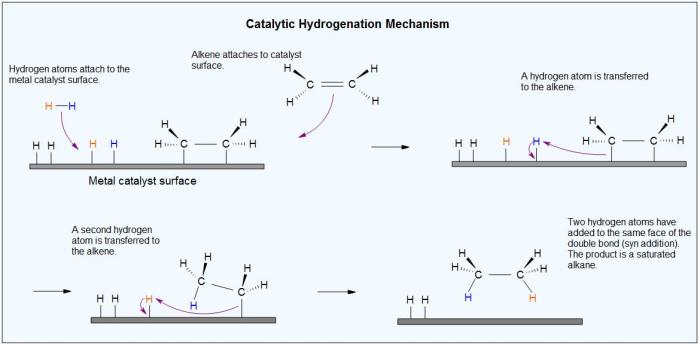

Hydrogenation is a chemical process that involves the addition of hydrogen to unsaturated fats, converting them into saturated fats. In the case of olive oil, hydrogenation is carried out to improve its stability, increase its shelf life, and alter its physical properties, such as melting point and texture.The

hydrogenation of olive oil is a complex process that involves several steps. The first step is the preparation of the oil, which involves removing impurities and moisture. The oil is then heated to a high temperature, typically between 160-180°C, and a catalyst is added.

The most commonly used catalysts are nickel and palladium.The catalyst plays a crucial role in the hydrogenation process. It provides a surface on which the hydrogen molecules can adsorb and react with the unsaturated fats. The catalyst also helps to reduce the activation energy of the reaction, making it proceed more quickly.The

hydrogenation reaction is exothermic, meaning that it releases heat. The heat generated during the reaction must be controlled to prevent the oil from overheating and degrading. The reaction is typically carried out under high pressure, typically between 20-40 atmospheres, to increase the solubility of hydrogen in the oil.The

hydrogenation process can be stopped at any point to achieve the desired level of saturation. The more hydrogen that is added, the more saturated the oil will become. The degree of saturation is typically measured by the iodine value, which is a measure of the number of unsaturated bonds in the oil.Hydrogenated

olive oil has a higher melting point and a longer shelf life than unhydrogenated olive oil. It is also more stable and less susceptible to oxidation. However, hydrogenation also reduces the nutritional value of the oil, as it converts the unsaturated fats into saturated fats.

Effects on Olive Oil Properties: Transfer Hydrogenation Of Olive Oil

Hydrogenation significantly alters the fatty acid composition, physical and chemical properties, and nutritional value of olive oil.

Changes in Fatty Acid Composition

- Hydrogenation converts unsaturated fatty acids (primarily monounsaturated oleic acid) into saturated fatty acids, increasing the proportion of saturated fats.

- This process reduces the content of healthy monounsaturated and polyunsaturated fatty acids, which are associated with various health benefits.

Changes in Physical and Chemical Properties

- Hydrogenation increases the melting point of olive oil, making it more solid at room temperature.

- It also alters the flavor and aroma of the oil, making it more bland and less fruity.

- Hydrogenation reduces the oxidative stability of olive oil, making it more susceptible to spoilage.

Effects on Nutritional Value

- Hydrogenation decreases the content of vitamin E, a powerful antioxidant found in olive oil.

- It also reduces the content of phytosterols, plant compounds that have been linked to reducing cholesterol levels.

- Overall, hydrogenation compromises the nutritional value of olive oil, making it less beneficial for health.

Industrial Applications

Hydrogenated olive oil finds widespread use in various industrial applications due to its unique properties, such as its high stability, resistance to oxidation, and neutral flavor profile. These characteristics make it a valuable ingredient in a range of products.

Food Industry

- Frying oils:Hydrogenated olive oil is commonly used as a frying oil in commercial kitchens and food processing facilities. Its high smoke point and resistance to oxidation make it suitable for high-temperature cooking, preventing the formation of harmful compounds.

- Margarine and shortenings:Hydrogenation converts olive oil’s liquid triglycerides into solid fats, enabling its use in the production of margarine and shortenings. These products are used in baking, pastries, and other food preparations.

- Confectionery fats:Hydrogenated olive oil provides a stable and flavorful fat source for confectionery products, such as chocolate, candy, and ice cream. It helps maintain the desired texture and flavor profile.

Non-Food Applications

- Lubricants:Hydrogenated olive oil’s high viscosity and resistance to oxidation make it a suitable base for lubricants in industrial machinery and automotive applications.

- Cosmetics and personal care:Hydrogenated olive oil is used in various cosmetic and personal care products, such as soaps, lotions, and hair care products. It provides emolliency and moisturizing properties.

- Biodiesel:Hydrogenated olive oil can be converted into biodiesel, a renewable fuel alternative to petroleum-based diesel. It reduces greenhouse gas emissions and provides a sustainable energy source.

Advantages and Disadvantages, Transfer hydrogenation of olive oil

- Advantages:

- High stability and resistance to oxidation

- Neutral flavor profile

- Versatile in various applications

- Disadvantages:

- May contain trans fats, which have been linked to health concerns

- Loss of some of the beneficial compounds found in unhydrogenated olive oil

Safety and Regulatory Considerations

The consumption of hydrogenated olive oil raises potential health concerns due to the presence of trans fats. Trans fats have been linked to an increased risk of cardiovascular diseases, including heart disease and stroke. Additionally, hydrogenated olive oil may contain other harmful compounds, such as saturated fats and oxidized lipids, which can further contribute to health risks.

Regulatory Frameworks

To ensure the safe consumption of hydrogenated olive oil, regulatory frameworks have been established in various countries and regions. These frameworks typically involve setting limits on the allowable trans fat content in food products. For example, the US Food and Drug Administration (FDA) has established a limit of 0 grams of trans fat per serving for food products labeled as “trans fat-free.”

The European Union (EU) has also implemented regulations to limit the trans fat content in food products, with a maximum limit of 2 grams of trans fat per 100 grams of fat.

Safety Measures

To ensure the safe consumption of hydrogenated olive oil, various safety measures are implemented. These measures include:

- Monitoring and Enforcement:Regulatory authorities conduct regular monitoring and enforcement activities to ensure compliance with established trans fat limits.

- Industry Standards:Food manufacturers and industry associations have developed voluntary standards to limit the trans fat content in their products.

- Consumer Education:Public health campaigns and educational initiatives aim to raise awareness about the health risks associated with trans fats and promote the consumption of healthier fats.

Query Resolution

What is the purpose of transfer hydrogenation of olive oil?

Transfer hydrogenation aims to modify the fatty acid composition of olive oil, enhancing its stability and suitability for specific industrial applications.

How does transfer hydrogenation affect the nutritional value of olive oil?

Hydrogenation reduces the unsaturated fat content and increases the saturated fat content of olive oil, potentially affecting its nutritional value.

What are the safety considerations associated with the consumption of hydrogenated olive oil?

Excessive consumption of hydrogenated olive oil may pose health concerns due to its increased saturated fat content.