Epa 608 test answers 2023 – Get ready to conquer the EPA 608 test with our exclusive 2023 answers guide. This comprehensive resource provides you with everything you need to pass with flying colors, empowering you to excel in refrigerant management and ensure a brighter future for our planet.

Our team of experts has meticulously crafted this guide to align perfectly with the latest EPA 608 exam format. Dive into the core concepts, master refrigerant identification and classification, and gain an in-depth understanding of refrigeration system components and operation.

Plus, you’ll learn troubleshooting and repair techniques, ensuring you’re equipped to handle any challenges that come your way.

EPA 608 Test Format and Structure

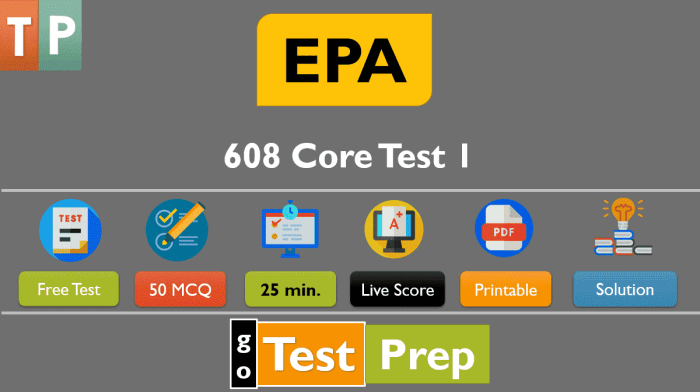

The EPA 608 certification exam is designed to assess an individual’s knowledge and understanding of federal regulations and proper handling practices for refrigerants. The test consists of three sections, each covering a specific aspect of refrigerant management:

Core Section

The Core section comprises 50 multiple-choice questions and has a time limit of 60 minutes. This section evaluates the candidate’s general knowledge of refrigerant regulations, environmental concerns, and safe handling practices.

Type I Section

The Type I section focuses on small appliances, and contains 25 multiple-choice questions to be completed within 30 minutes. This section tests the candidate’s understanding of refrigerant handling and recovery procedures for appliances containing less than 5 pounds of refrigerant.

Type II, III, or Universal Section

Candidates can choose to take either the Type II, Type III, or Universal section, depending on their desired certification level. Each of these sections contains 25 multiple-choice questions and has a time limit of 30 minutes.

While preparing for the EPA 608 test in 2023, you may find yourself searching for the answers. However, taking a break to delve into the captivating world of A Wrinkle in Time Pegasus can offer a refreshing respite. The novel’s exploration of themes like time travel and self-discovery can provide a thought-provoking interlude before returning to the challenges of the EPA 608 test answers.

Type II

High-pressure refrigerants

Type III

Low-pressure refrigerants

Universal

Covers both high- and low-pressure refrigerants

Core Refrigerant Management Topics: Epa 608 Test Answers 2023

The EPA 608 test covers the essential aspects of refrigerant management, including handling, recovery, disposal, and compliance with regulations. Proper refrigerant management is crucial for protecting the environment, ensuring safety, and maintaining efficient HVAC systems.

Proper Refrigerant Handling

Handling refrigerants safely requires knowledge of their properties, potential hazards, and proper storage and transportation techniques. Technicians must be trained to identify and use the correct tools and equipment for handling refrigerants, including leak detectors, recovery machines, and refrigerant cylinders.

Refrigerant Recovery and Disposal

Refrigerant recovery is essential for preventing the release of harmful substances into the atmosphere. Technicians must be familiar with recovery procedures, including the use of recovery machines, proper disposal methods, and the importance of recycling refrigerants. Proper disposal techniques involve following regulations and industry best practices to minimize environmental impact.

Regulations and Safety Protocols

The EPA and other regulatory bodies have established strict regulations for refrigerant management. These regulations include requirements for technician certification, refrigerant handling practices, recovery and disposal procedures, and recordkeeping. Safety protocols are also essential to prevent accidents, injuries, and environmental damage.

These protocols include wearing appropriate personal protective equipment, using proper ventilation, and following established safety guidelines.

Refrigerant Identification and Classification

Refrigerants are the lifeblood of refrigeration and air conditioning systems, responsible for absorbing and releasing heat to cool or warm our spaces. The EPA 608 certification exam places significant emphasis on refrigerant identification and classification, ensuring technicians possess a thorough understanding of these substances.

Refrigerant Classification

Refrigerants are classified into various groups based on their chemical composition and properties. The most common classification system is the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) standard, which assigns refrigerants a number designation.

- Chlorofluorocarbons (CFCs):CFCs, such as R-11 and R-12, were once widely used but have been phased out due to their ozone-depleting potential.

- Hydrochlorofluorocarbons (HCFCs):HCFCs, like R-22, are transitional refrigerants with reduced ozone-depleting potential compared to CFCs.

- Hydrofluorocarbons (HFCs):HFCs, including R-134a and R-410A, are non-ozone-depleting refrigerants but have high global warming potential.

- Hydrofluoroolefins (HFOs):HFOs, such as R-1234yf, are low-global-warming-potential refrigerants with reduced flammability.

- Natural Refrigerants:Natural refrigerants, like ammonia (R-717) and carbon dioxide (R-744), have minimal environmental impact but may require specialized equipment.

Refrigerant Properties

In addition to classification, refrigerants are characterized by various properties that influence their use and application. These properties include:

- Boiling Point:The temperature at which a refrigerant transforms from a liquid to a gas.

- Condensing Temperature:The temperature at which a refrigerant releases heat and condenses into a liquid.

- Pressure:The force exerted by a refrigerant as it flows through a system.

- Toxicity:The potential of a refrigerant to cause harm to human health or the environment.

- Flammability:The ease with which a refrigerant can ignite and burn.

Refrigerant Applications

The choice of refrigerant depends on several factors, including the type of refrigeration or air conditioning system, the desired cooling capacity, and environmental regulations.

- CFCs:Once used in various applications, CFCs are now banned due to their ozone-depleting potential.

- HCFCs:HCFCs are being phased out but are still used in some older systems.

- HFCs:HFCs are widely used in residential and commercial refrigeration and air conditioning systems.

- HFOs:HFOs are gaining popularity as low-global-warming-potential alternatives to HFCs.

- Natural Refrigerants:Natural refrigerants are used in specialized applications, such as industrial refrigeration and heat pumps.

Understanding refrigerant identification and classification is crucial for EPA 608 certification. By comprehending the different types of refrigerants, their properties, and applications, technicians can ensure the safe and efficient operation of refrigeration and air conditioning systems.

Refrigeration System Components and Operation

Refrigeration systems are crucial in various industries and applications, providing cooling and temperature control. To understand their operation effectively, it’s essential to identify and comprehend the functions of their major components.

Compressor

The compressor is the heart of the refrigeration system, responsible for compressing the refrigerant vapor. This compression increases the refrigerant’s pressure and temperature, initiating the refrigeration cycle.

Condenser

The condenser is a heat exchanger that removes heat from the compressed refrigerant vapor, causing it to condense into a liquid. This heat transfer process releases the heat absorbed from the refrigerated space.

Expansion Device, Epa 608 test answers 2023

The expansion device, such as a capillary tube or thermostatic expansion valve, regulates the flow of liquid refrigerant into the evaporator. It controls the pressure and flow rate of the refrigerant entering the evaporator.

Evaporator

The evaporator is another heat exchanger that absorbs heat from the refrigerated space. The liquid refrigerant expands into a vapor within the evaporator, extracting heat from the surrounding environment.

Refrigerant Flow

The refrigerant circulates through the system in a closed loop. The compressor draws low-pressure refrigerant vapor from the evaporator and compresses it, raising its pressure and temperature. The high-pressure refrigerant vapor then flows into the condenser, where it releases heat and condenses into a liquid.

The liquid refrigerant passes through the expansion device, which reduces its pressure and temperature. The low-pressure liquid refrigerant enters the evaporator, where it absorbs heat from the refrigerated space and vaporizes. The refrigerant vapor returns to the compressor, completing the cycle.

Heat Transfer

Refrigeration systems utilize heat transfer processes to achieve cooling. The evaporator absorbs heat from the refrigerated space, while the condenser releases heat to the surrounding environment. This heat transfer is facilitated by the refrigerant’s phase changes between liquid and vapor.

Troubleshooting and Repair

Troubleshooting and repairing refrigeration systems require a systematic approach to identify the root cause of the issue and implement effective solutions. This involves understanding the system components, refrigerant flow, and potential failure points.Proper leak detection and repair methods are crucial to ensure the safe and efficient operation of refrigeration systems.

Identifying and sealing leaks promptly prevents refrigerant loss, reduces energy consumption, and minimizes environmental impact.

Safety and Environmental Regulations

Safety and environmental regulations play a crucial role in handling refrigerants. Understanding these regulations ensures the protection of technicians, the public, and the environment.

Safety Regulations for Working with Refrigerants

- Always wear appropriate personal protective equipment (PPE) when working with refrigerants, including gloves, safety glasses, and respiratory protection.

- Ensure adequate ventilation in work areas to prevent refrigerant buildup.

- Never smoke or use open flames near refrigerants, as they are flammable.

- Handle refrigerants only in well-ventilated areas, and avoid prolonged exposure to high concentrations.

- Train personnel on safe handling practices, including leak detection and emergency procedures.

Environmental Impact of Refrigerant Emissions

- Refrigerants are potent greenhouse gases that contribute to climate change.

- Releasing refrigerants into the atmosphere damages the ozone layer and contributes to global warming.

- It is essential to minimize refrigerant emissions by properly installing, maintaining, and servicing refrigeration systems.

Proper Refrigerant Disposal and Recycling Procedures

- Never release refrigerants into the atmosphere.

- Recover refrigerants using certified equipment and follow proper disposal procedures.

- Recycle refrigerants to reduce environmental impact and conserve resources.

- Dispose of refrigerants according to local and federal regulations, which may involve specialized facilities or licensed waste handlers.

Query Resolution

What is the format of the EPA 608 test?

The EPA 608 test consists of 80 multiple-choice questions divided into four sections: Core, Type I, Type II, and Type III. You’ll have 120 minutes to complete the exam.

What topics are covered in the EPA 608 test?

The EPA 608 test covers a wide range of topics related to refrigerant management, including proper handling, recovery, and disposal techniques, as well as regulations and safety protocols.

How can I prepare for the EPA 608 test?

The best way to prepare for the EPA 608 test is to study the official EPA study materials and take practice exams. Our 2023 answers guide is an excellent resource to help you succeed.